Warp Knitting. - ppt video online download

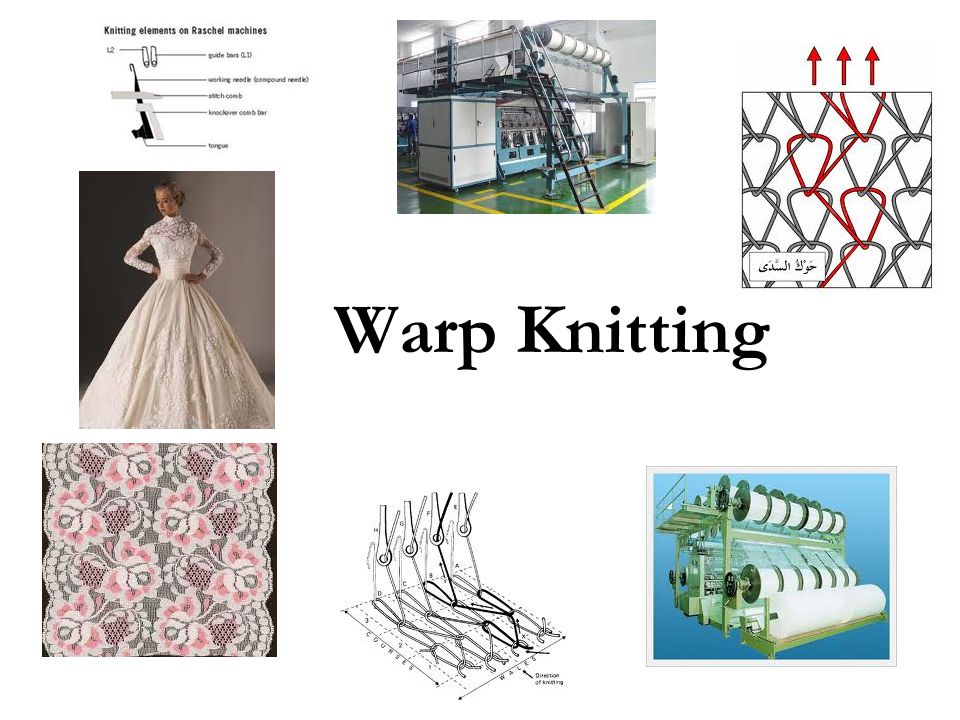

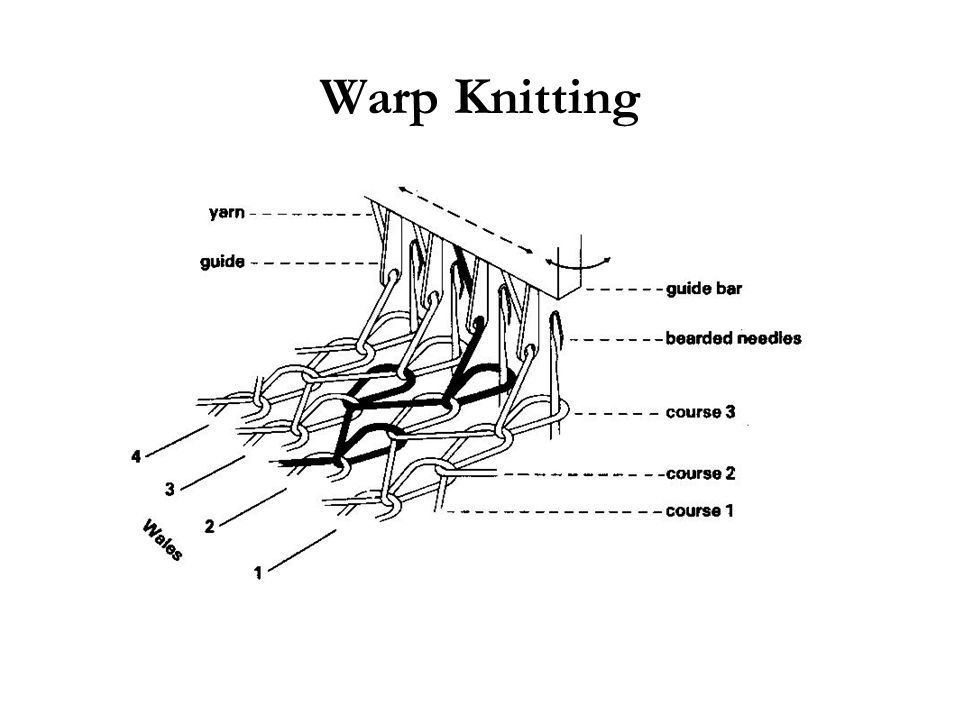

Warp Knitting Warp knit fabric is produced from a set of warp yarns, normally using at least one yarn per wale, knitted parallel to each other down the length of the fabric.

It involves the preparation of warp beam. Yarns zigzag from side to side along the length of the fabric. One yarn for each needle. Yarns to be wrapped around the needle to form loops and stitches.

Weft Knitting vs Warp Knitting

Yardage, shaped garments, garment parts and finished products can be produced. Fabric tends to stretch in width and length. Fabric may run or ravel. Rapid changeover to new design. Production may be flat or circular. Produces yardage only. Limited stretch. Some in width, less in length. Do not run or ravel easily. Slower and more costly changeover to new designs. Flat only.

The warp knitted fabric is formed by knitting the warp yarns on adjacent needles course by course and intermesh the loops with the neighbouring yarns to form fabric.

required 1000 wales, then there must be 1000 warp yarns on the. beam and slightly more than 1000 needles on machine.

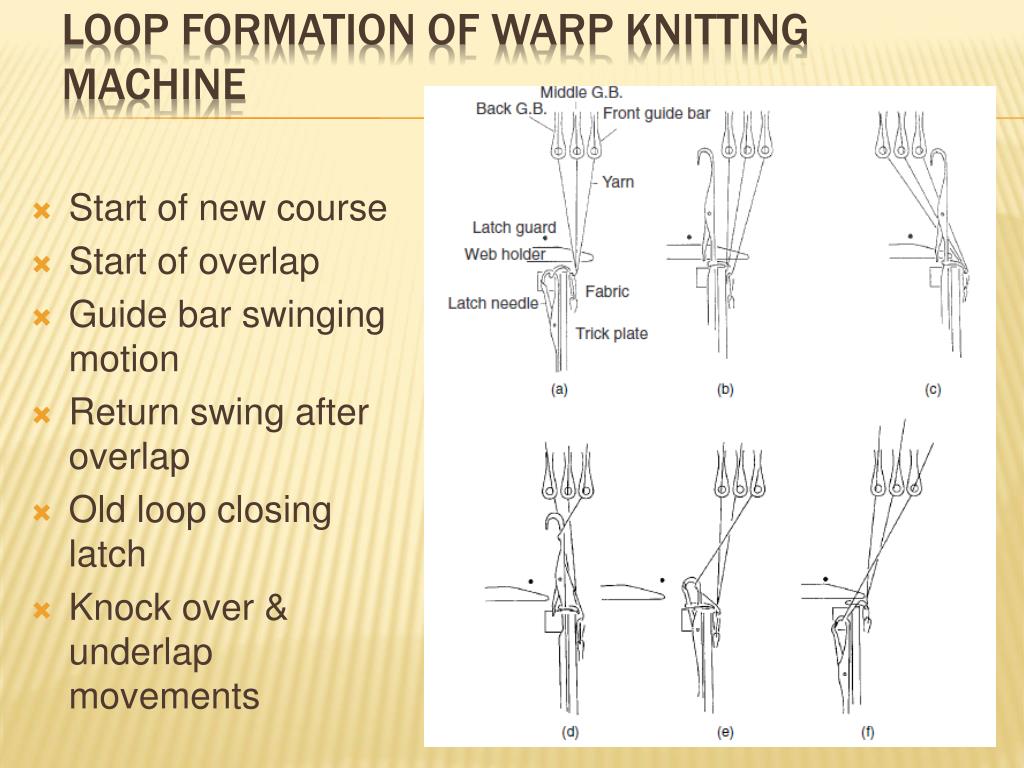

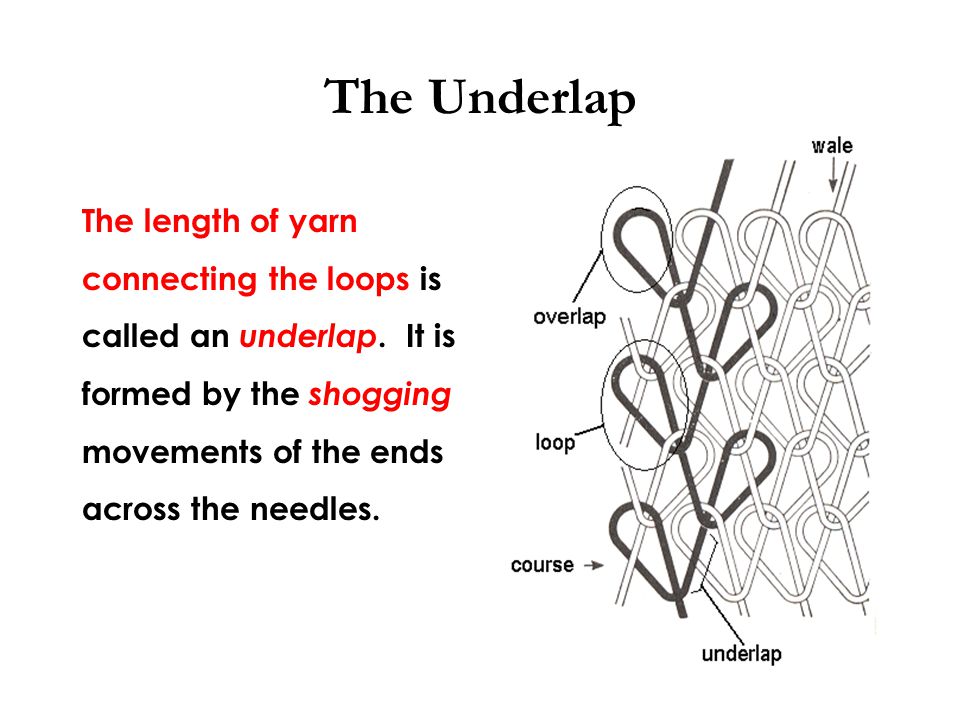

Warp Knitted Loop. Made of two parts: The overlap. The underlap.

The Overlap Formed by the yarn being wrapped around the needle and drawn through the previous loop.

It is formed by the shogging movements of the ends across the needles.

A course (2) is a horizontal row of loops formed by the needles during one knitting cycle. In warp knitting, all the needles perform the knitting action simultaneously so that one knitted course is formed across the whole width of the knitting machine for every turn of the main shaft.

The number of wales in the fabric equals to the number of needles.

The guide bar: Threading yarn to produce lapping movement. Minimum number : 2, move at opposite direction.

Metal lead attached to the guide bar. Guide has the same gauge as the needles.

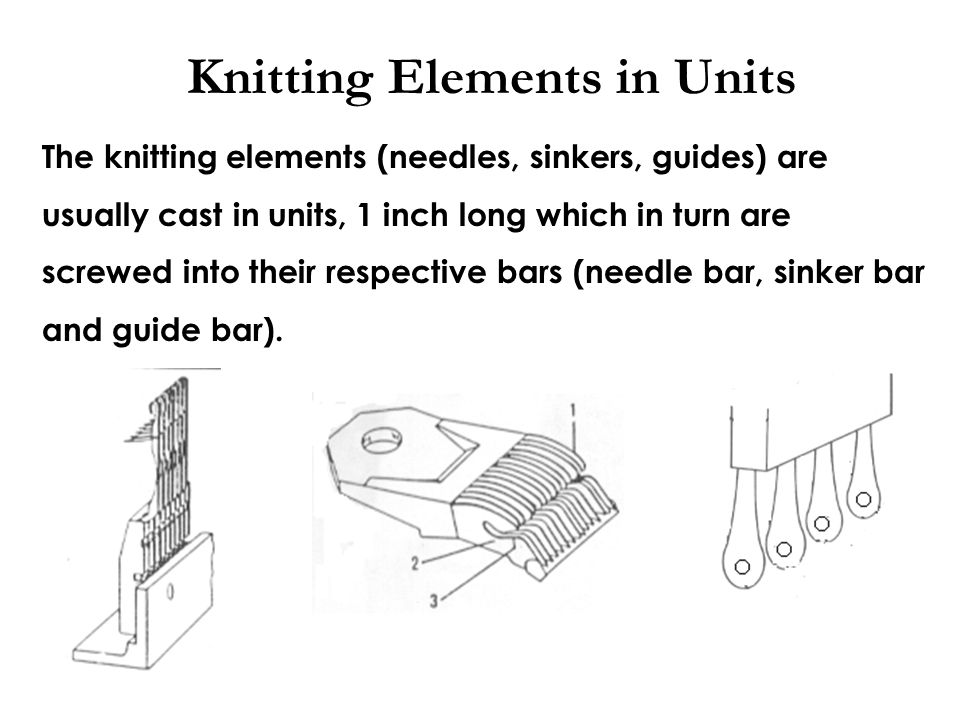

The knitting elements (needles, sinkers, guides) are usually cast in units, 1 inch long which in turn are screwed into their respective bars (needle bar, sinker bar and guide bar).

warp thread setting on guide bars; and. lapping movement of the guide bars. For a simple single guide bar, single colour fabric, the structure is based on the lapping movement of the guide bar.

Guide Bar Movements Lapping motion: Swinging motion Shogging motion

Is a collective movement for all the guide bars as they pivot on a common rocker shaft. The two swinging movements produce the two side limbs of the warp knitted loop.

Extent, timing, direction of underlaps and overlaps controlled for each guide bar by its own pattern chain links or pattern wheel. Produces underlaps and overlaps.

Different Height of. Links control the lapping. movement.

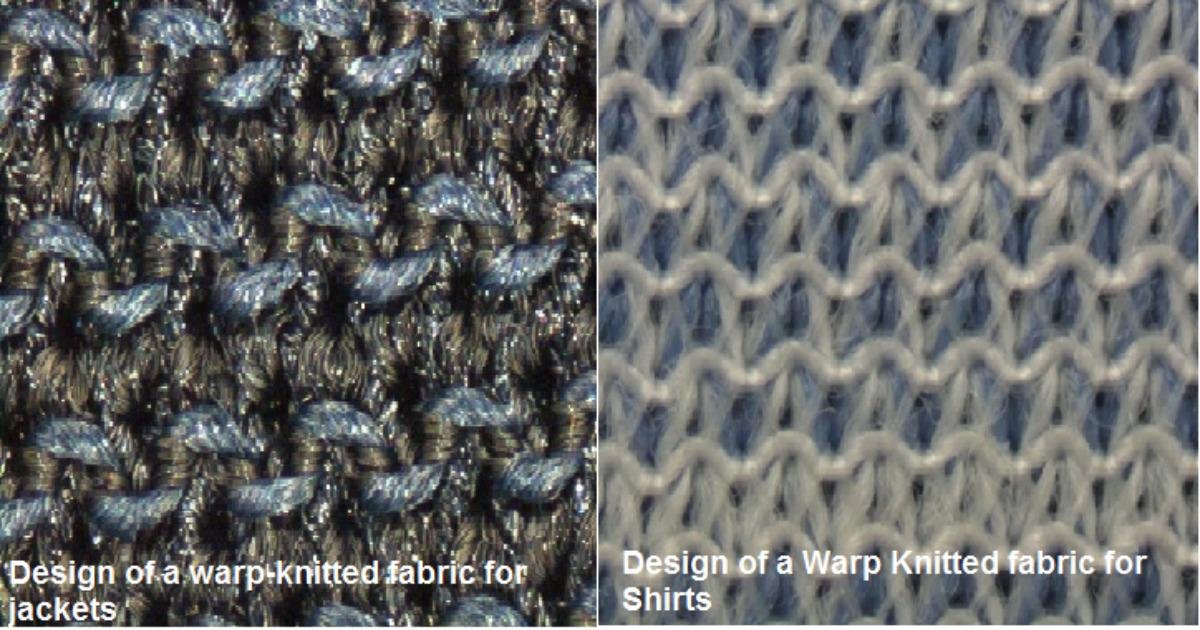

Machinery : use spring beard, latch or compound needles. Fine gauge only. Fine denier filament and textured filament. Simple design and small geometrics. Uses: Lingerie, swimwear, sleepwear, bonded backnig fabric, sportwears, upholstery, skirt n blouses. Latch needles. Fine to course gauge. Spun and filament, all count and denier. Large and intricate designs, but not as versatile as weaving or weft knitting. Uses: laces and trim, nets, dress fabrics, sweater fabrics, thermal kint for underwear, blankets, curtains.

1-2 indicates the guide bar is doing overlap from needle. position 1 to 2 ie. From right to left for one needle. 1-0 indicates the yarn is fed to the needles from the left to. right for one needle space.

for a repeat structure. When thousands of warp threads are on the same. guide bar, and all the warp threads are doing the same movement, a. knitted fabric is formed.

All warp knit fabric structures are composed of both overlap and underlap.

The result is that each needle knits a chain of stitches. Example: 1-0/01, known as pillar stitch. A pillar stitch is not a fabric, but is commonly used with other lapping movements to form a fabric.

Formed when needles are lapped continuously by the same guides. Since the guides do not lap the adjacent needles, there are no sideways connections and no fabric is formed.

Closed Pillar Stitch. 1-0/1-0. Open Pillar Stitch. 1-0/0-1.

If a guide bar only made underlaps in a multi-guide structure, this guide bar is called inlay bar and the warp are called inlay yarn, which never form into loops but only tie-in at the back of the fabric.

1. When overlap and underlap are moving the same direction, an open lap fabric will be formed. 2. When overlap and underlap are moving in opposite direction, closed lap will be produced.

1 X 1 Open Lap Fabric 1 X 1 Closed Lap Fabric

This seems to be warp float in the fabric. The guide bars give no lateral movements for a few courses in the repeat, laying the warps straight in the fabric. For a multi guide bar fabric, it is used to hide colour warps at the back for a colour pattern.

The 1 X 1 lap is the basic formation of warp knit fabric. The guide bar feeds yarn on a needle in the first course, and then it moves sideways to feed yarn on the neighbouring needle in the second course and repeat. All the warp knit fabrics are formed in the similar manner, except that there might be more guide bars used, more courses per repeat, or different underlaps and different direction of guide bar shogging.

The difference between these three fabrics is the amount of guide bar shogging for underlaps. Fabric weight: 3x1 > 2x1 > 1x1. Finished Width: 3x1 < 2x1 < 1x1.

Low strength, Lack of stability, Poor covering power, Distortion caused by loop inclination.

More balanced structures are achieved by having two sets of warp threads underlapping in opposition from each other so that underlaps of each enter and leave from opposite sides of the head loop.

Warp structures with two sets of guide bars

This is a balanced structure, the two set of warp yarns are doing their overlap in opposite direction. This result in perfect upright loops in the fabric surface. BGB: 1-2/1-0. FGB: 1-0/1-2.

Full Tricot. Technical face: fabric side with the loops showing on the surface. Technical back: fabric side with the underlaps showing on the surface.

Although all structures have their overlap and underlaps in the opposite direction, but the underlap displacements of the two bars are different. Locknit is one of the examples. The FGB makes a longer underlap than BGB, and the result is the fabric will give lower sideway elasticity than tricot. BGB: 1-2/1-0. FGB:1-0/2-3.

Reverse Locknit FGB: 1-0/1-2 BGB:2-3/1-0

The Sharkskin which has a longer underlap. 4-5/1-0 on the BGB, will be even heavier in weight.

The pillar stitches act as warp yarns and the long underlaps act as weft yarns in the fabric. Therefore, its dimensional stability should be near to the woven fabrics. FGB: 1-0/0-1. FGB: 2-3/1-0.

Write down the lapping movements, chain notations for the given loop diagrams

The lapping movement of guide bar moves in one direction for a number of courses and then return; this changes the direction of inclination of loops.

The two guide bar (double atlas) will give a solid vertical wales and is more stable than single atlas. Normally double atlas is knitted with colour patterns.

FGB=2-3/2-1/1-0/1-2. BGB=1-0/1-2/2-3/2-1.

The 2 bar Marqiosette os a see through net fabric composed. of square cells, is used for low cost curtain net. FGB:1-0/0-1. BGB:0-0/1-1/0-0/3-3/2-2/3-3.

Raschel Warp Knit Lace, pantyhose

PPT - Knitting technology PowerPoint Presentation, free download - ID:1429651

Warp Knitting. - ppt video online download

Knitted fabric

Warp Knit Basic Structure - ppt video online download

Warp knitting

Knitted fabric

Warp knitting

Warp knitting

Warp knitting

Warp Knitting. - ppt video online download

Warp knitting

Warp Knitting. - ppt video online download